Diara’s world of flavor

Symphony of Flavor & Fragrance

Food industry

cosmetics

Research and development department

Diara Media

between us

contact us

Farsi

English

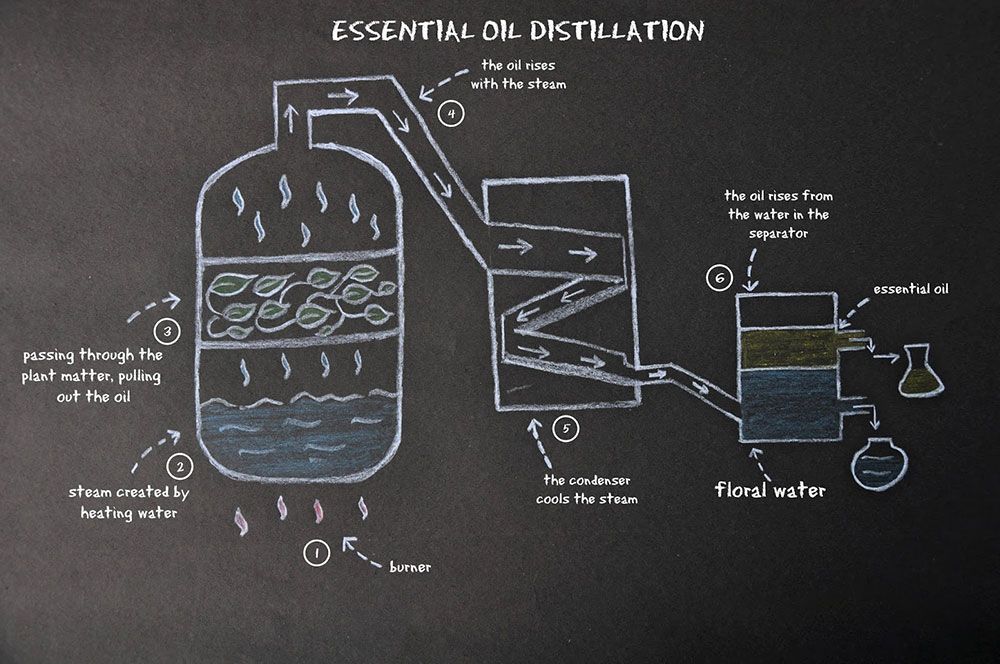

The most widely used method for extracting essential oil is steam distillation due to its simplicity and the need for low investment. Considering the importance of this extraction method, technological advances are a huge opportunity to improve this part of essential oil production. In order to evaluate how such updates have been applied in essential oil production, in this study, a technological review has been conducted. A total of 490 patent documents were retrieved and indicators including the publication process, main applicants and inventors of the desired technologies, main depositing countries and potential markets for the inventions and classification codes assigned to the patent documents were evaluated. The results showed that steam distillation is used in different sectors and is a growing and important industrial process in recent years. In terms of the up-to-dateness of the related technology, it was observed that only some patent documents refer to the application of technological updates, indicating that the processes can still be explored and incorporated into the current technology. Therefore, the progress of studies to improve this process can further contribute to the clear growth, increasing the application potential and efficiency of the process.

Eucalytus-essential-oil-distillation-scaled

Industrial improvement of essential oil extraction by steam distillation

Introduction

Essential oils are products that are extracted from different parts of plants such as leaves, stems, roots and bark. Chemically, essential oils (EOs) are homogeneous mixtures composed of various fractions from the most volatile to the heaviest terpenoids. These compounds are natural, usually produced as secondary metabolites and act as defense phytochemicals for plants. Terpenoids have a prominent aroma that is often pleasant to the human sense of smell. These compounds, with the exception of rare cases, have a lower density than water, they exist with a specific color for everything, and its intensity is also different, and their presence is important in plant species. Essential oils with properties such as aroma, flavor and medicinal properties play an important role in various industry sectors such as supplying raw materials for cosmetics, pharmaceuticals, aromatherapy, food flavorings, preservatives and home businesses. Large-scale production of essential oils is a driving force in the global market. However, high market prices are often a major obstacle. However, the high demand for essential oils, especially for use as natural preservatives, has provided growth opportunities in global markets.

The global Essential Oils market size was estimated at USD 10.3 billion in 2021 and is expected to reach USD 16.0 billion by 2026. The increasing consumption of natural products due to their health benefits has prompted manufacturers to invest in EOs instead of using synthetic ingredients in their commercial products, including cosmetics, pharmaceuticals, food, etc. Therefore, continuous growth in the market of essential oils (essential oils) is not far from expected.

Steam Distillation for Essential Oil Extraction

In order to contribute to the potential commercialization of essential oils, production must be aligned to conditions that provide good process efficiency and high quality. One of the main challenges in scaling the production of essential oils is the extraction process, due to the long time and high energy requirements, in general, the extraction process includes azeotropic distillation or solvent extraction. Azeotropic distillation includes water distillation, hydrodiffusion and steam distillation. Steam distillation extraction is known for performance and process uncertainty. However, it is still the most practical extraction method due to its low investment and operating costs compared to other extraction methods, such as supercritical carbon dioxide extraction, microwaves, ultrasound, and nonpolar solvents. The steam distillation extraction method is an environmentally green method because the solvent used in it is water vapor, compared to organic solvents that require separation after extraction, produce waste, require air purification, and sometimes use They have unauthorized facilities.

Steam distillation extraction in the EO industry usually results in low yields and long extraction times compared to the high consumption of other sources. However, on a laboratory scale, experiments have shown that the amount of oil in the green matrix is higher than that usually obtained by industry. This suggests that industrial equipment for steam distillation extraction can be modified to achieve higher yields, better quality and shorter extraction periods.

Steam Distillation for Essential Oil Extraction

The importance of steam distillation method in essential oil extraction

The use of technological updates in the steam distillation process for the extraction of essential oils can improve process control and results and bring significant opportunities to the industrial sector. These updates are part of a wave called Industry 4.0, a trend that is directly related to issues of process reliability, availability and the creation of industrial innovations. Due to the aforementioned growth in the use of natural products such as EOs, there is a need to achieve higher yields, better quality and shorter extraction periods.

Technological upgrades can enhance the characteristics of the steam distillation process, such as reducing material degradation, increasing the quality of the final product, and obtaining higher EO yields. In addition, the benefits of A

25 دی 1402

25 دی 1402  0

0

Comments

Be the first one to post your opinion